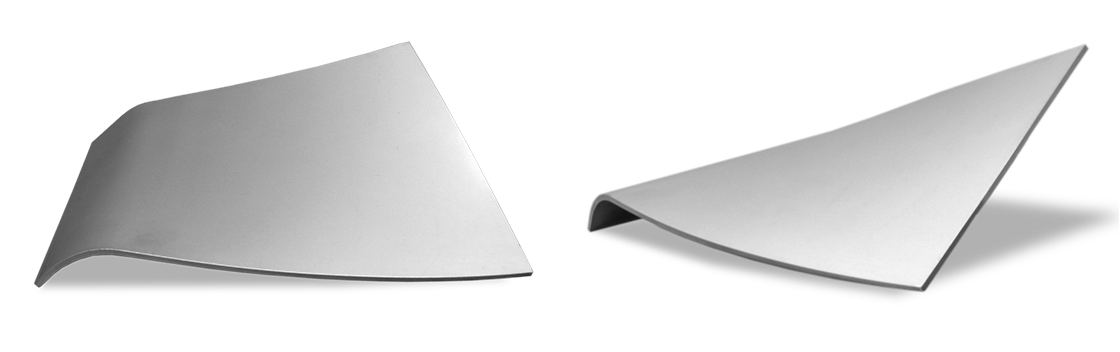

Elastoforming is a technology for working sheet metal widely used in aeronautics applications where for safety reasons technical regulations do not allow the forming of sheet metal by a die in which the punch and matrix are also metal.

The elastoplastic molding technology, indeed, allows to obtain molded components due to the pressure exerted on the die against an flexible elastimeric matrix (made of rubber or polymers). Our large press with a force of 6000 and 7000 tonnes are also suitable for sheet metal elastoforming. This method eliminates the usual stress on the metal, caused by traditional molding process, and enables the easy duplication of the pieces, while maintaining the reduced cost and a limited numbers of tools. It’s estimated that the elastoforming guarantees a reduction of up to 50% of investments for dies, with a higher surface and dimensional quality of the product.

For the product:

For the process:

Elastoforming also allows a different approach to the conventional product development: why I should cut, bend, weld (and brush in the case of stainless steel) when a press machine can do it all, with a minimum outlay for a die?